Yesterday I washed raw wool for the first time. I thought it would be a piece of cake thanks to youtube. And of course, nothing is every as easy as it looks. I didn't want to use the washing machine like some sites recommended because we don't own the one in our apartment- I didn't want to be in the position of "whoops sorry broke the washing machine while washing wool" (It's an old washer - with a new one I wouldn't have been as worried).

So - I used the bathtub. The two fleeces I bought, one mohair (white) and one alpaca (black/grey) were dirtier than I thought possible so it took several rinsings to reach a water color that wasn't dark brown. It's now drying in a sheet hammock outside and on our living room floor. Classy. Some of it felted because I didn't know what I was doing, but most of it is salvageable and I've begun carding some of it. After all that work it's nice to see the fluffy end product.

Apparently I was talking in the middle of the night recently and sat up and said "the wool, the yarn, and the felt". Clearly I have a one track mind, even while sleeping.

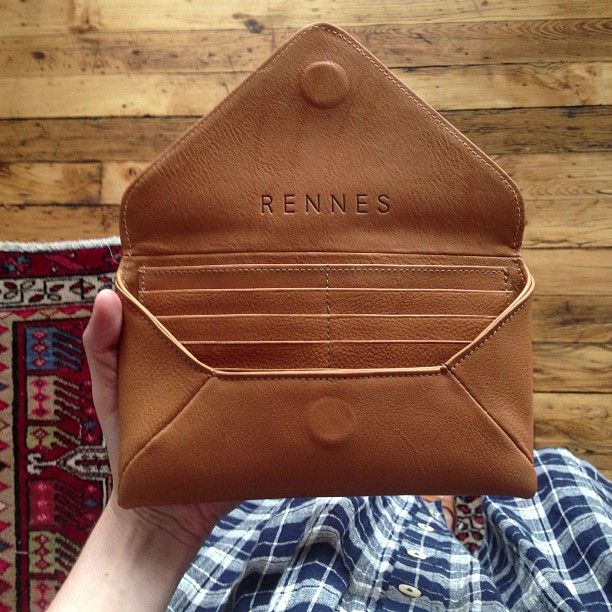

And now today I'm spending the day figuring out what I'm doing with my business. I'm at a bit of a breaking point and don't know what to do. It's even getting to the point where, yes, after four and half years, I'm writing a detailed business plan. Above is the second sample made of the Milo Wallet. It's a little different and better than the one I make: it has turned edges and a magnetic closure and I'm happy with it.

It seems like I'm not going to be able to put all my line into production at once like I anticipated and I'm sad about that. Having things made in an American factory is expensive. I am constantly questioning whether it's worth it, and whether my customers are going to be willing to pay that additional cost. The sampling and dies will cost around $4000. If I order 25 wallets, each wallet will be $66 which includes materials. So, a preliminary run costs $1,650. I currently sell this wallet for $160 on my shop. Let's say I just do a 2X mark up - making $132 wholesale and then, let's say my shop (or a retailer) does a 2X mark up - that makes it $264. Which is a lot more than $160 and probably more than most would pay for a wallet. So you can see the pickle that I'm in.

A different factory I spoke with said if I want to keep similar prices to what I already have it's a better option for me to have things made in China. That's so discouraging.